You're now following

Error following user.

This user does not allow users to follow them.

You are already following this user.

Your membership plan only allows 0 follows. Upgrade here.

Successfully unfollowed

Error unfollowing user.

You have successfully recommended

Error recommending user.

Something went wrong. Please refresh the page and try again.

Email successfully verified.

indore, india

It's currently 8:04 PM here

Joined January 1, 2020

8 Recommendations

Abbas J.

@SMBelectronics

6.0

6.0

94%

94%

indore, india

89%

Jobs Completed

84%

On Budget

81%

On Time

9%

Repeat Hire Rate

Electronics Engineer | Hardware & PCB Expert

Contact Abbas J. about your job

Log in to discuss any details over chat.

Portfolio

Portfolio

2.5 Gbps SerDes design using TLK2501

2.5 Gbps SerDes design using TLK2501

65W LED driver circuit

65W LED driver circuit

65W LED driver circuit

65W LED driver circuit

65W LED driver circuit

65W LED driver circuit

65W LED driver circuit

Glucometer

Glucometer

Glucometer

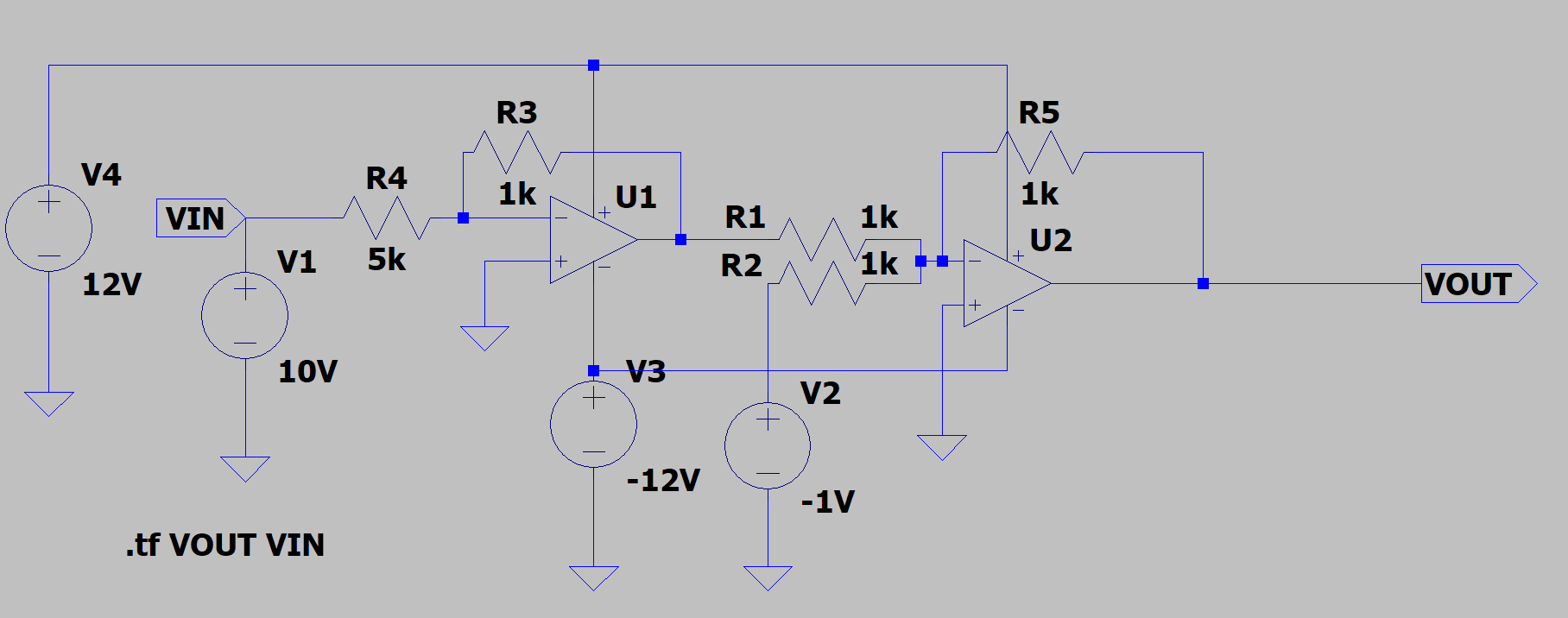

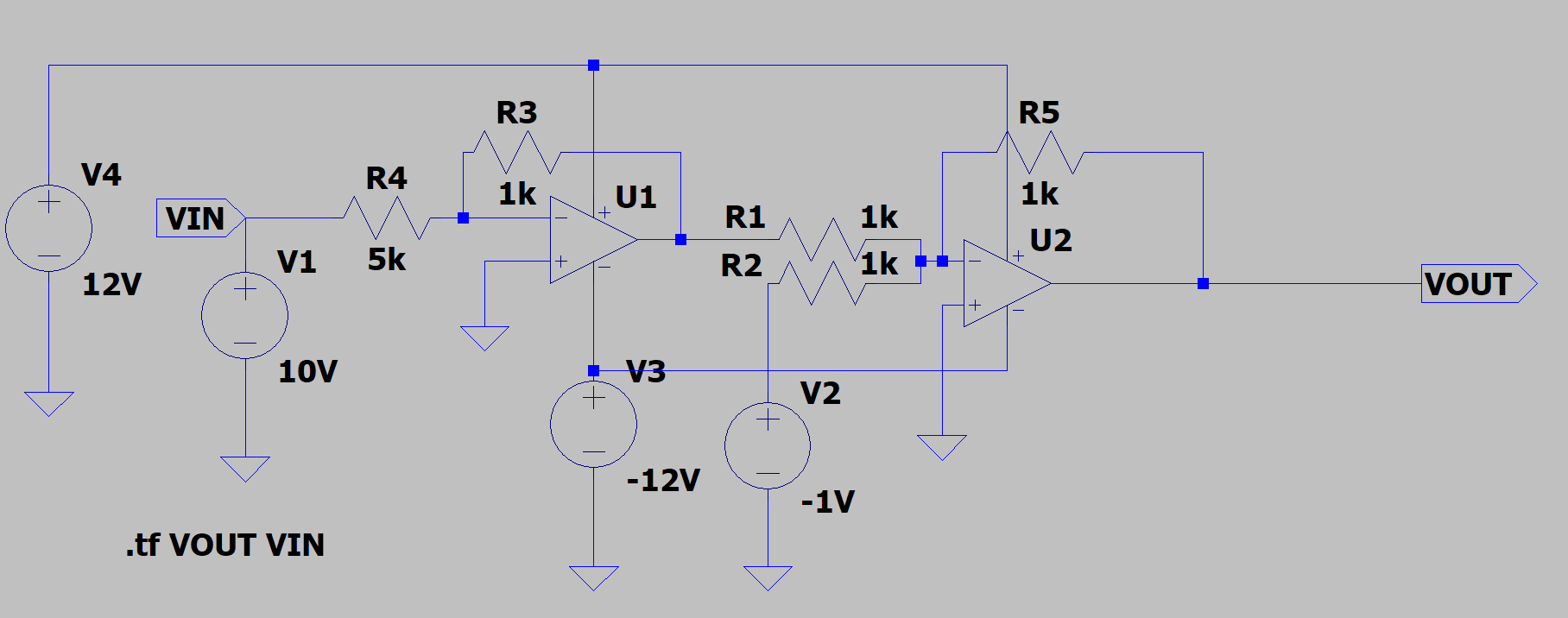

0-10V to 1-3V signal converter

0-10V to 1-3V signal converter

0-10V to 1-3V signal converter

PCB routing for BLE SoC

Ace-box data logger

Ace-box data logger

Ace-box data logger

2.5 Gbps SerDes design using TLK2501

2.5 Gbps SerDes design using TLK2501

65W LED driver circuit

65W LED driver circuit

65W LED driver circuit

65W LED driver circuit

65W LED driver circuit

65W LED driver circuit

65W LED driver circuit

Glucometer

Glucometer

Glucometer

0-10V to 1-3V signal converter

0-10V to 1-3V signal converter

0-10V to 1-3V signal converter

PCB routing for BLE SoC

Ace-box data logger

Ace-box data logger

Ace-box data logger

Reviews

Changes saved

Showing 1 - 5 out of 50+ reviews

$300.00 USD

Electronics

Electrical Engineering

PCB Layout

Product Design

Circuit Design

•

₹12,500.00 INR

Electronics

Microcontroller

PCB Layout

Arduino

Circuit Design

A

•

₹5,000.00 INR

Electronics

Microcontroller

Electrical Engineering

PCB Layout

Circuit Design

M

•

$500.00 USD

Electronics

Microcontroller

Electrical Engineering

PCB Layout

Circuit Design

L

•

Price undisclosed

Electronics

Electrical Engineering

PCB Layout

P

•

Experience

Electronic Engineer

Aug 2018 - Jan 2020 (1 year, 5 months)

At 3d prototyperz, I worked as Electronics Engineer and was responsible for designing developing and programming electronics systems for 3d printers and other machineries

Education

Bachelors of Engineering

(4 years)

Contact Abbas J. about your job

Log in to discuss any details over chat.

Verifications

Certifications

Top Skills

Browse Similar Freelancers

Browse Similar Showcases

Invite sent successfully!

Thanks! We’ve emailed you a link to claim your free credit.

Something went wrong while sending your email. Please try again.

Loading preview

Permission granted for Geolocation.

Your login session has expired and you have been logged out. Please log in again.